This is a Symmetry Electronics article previously posted here Also be sure to check out a range of Technical Articles and product datasheets here.

Author: Product Manager Patrick Reith

Sensirion extends the possibilities of thermal flow measurement in laboratory analytics and industry. With the help of a new design, engineers have succeeded in developing a high-flow sensor with significantly higher liquid flow rates of up to 1 liter per minute. The Swiss manufacturer is thus advancing into a new dimension of accurate flow measurement and expanding their portfolio.

ated.View Post

Although measuring higher flow rates with Coriolis mass flow meters or ultrasonic flow meters is very accurate, it is not an option for many applications for two reasons: the technology is costly and takes up a lot of space. The low-cost paddlewheel sensors, on the other hand, are too inaccurate for many requirements and do not provide a calibrated output signal. Users also complain about a lack of process reliability, as the measuring wheel can get jammed in the flow channel. Sensirion now closes the gap with a cost-effective liquid flow sensor for laboratory analysis and industry that accurately measures higher flow rates in the usual Sensirion quality, just 5 cm long and just 7 g in weight.

Thermal limitation overcome by steel membrane

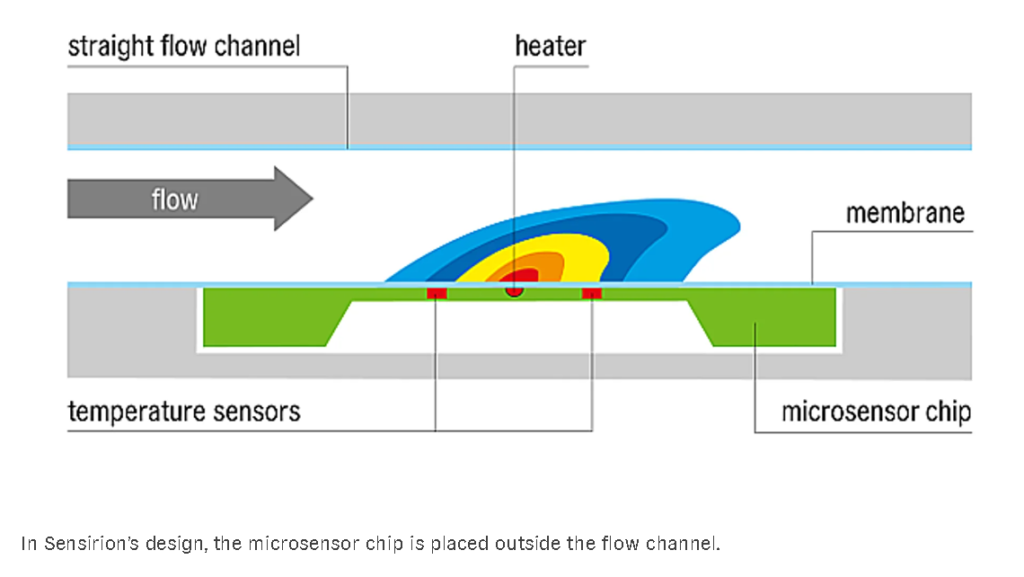

Here, the company relies on its proven mode of operation: A microscopic heating element adds a tiny “heat cloud” to the liquid, which is deformed by the flow. Two highly sensitive microsensors measure the temperature before and after the heating element and record the deformation of the heat cloud, which manifests itself in a temperature difference between the two sensors. The microchip converts the value to a fully calibrated and linearized flow rate and provides it as an output signal. So as not to disturb the flow, and to protect the sensor chip from influences caused by the liquid, Sensirion places the microsensor chip outside the flow channel. The flow rate is thus measured “through the channel wall,” which means that both the heat from the heater and the signals from both temperature sensors pass through the membrane. As a consequence, the thermal properties of the membrane significantly influence the sensor performance.

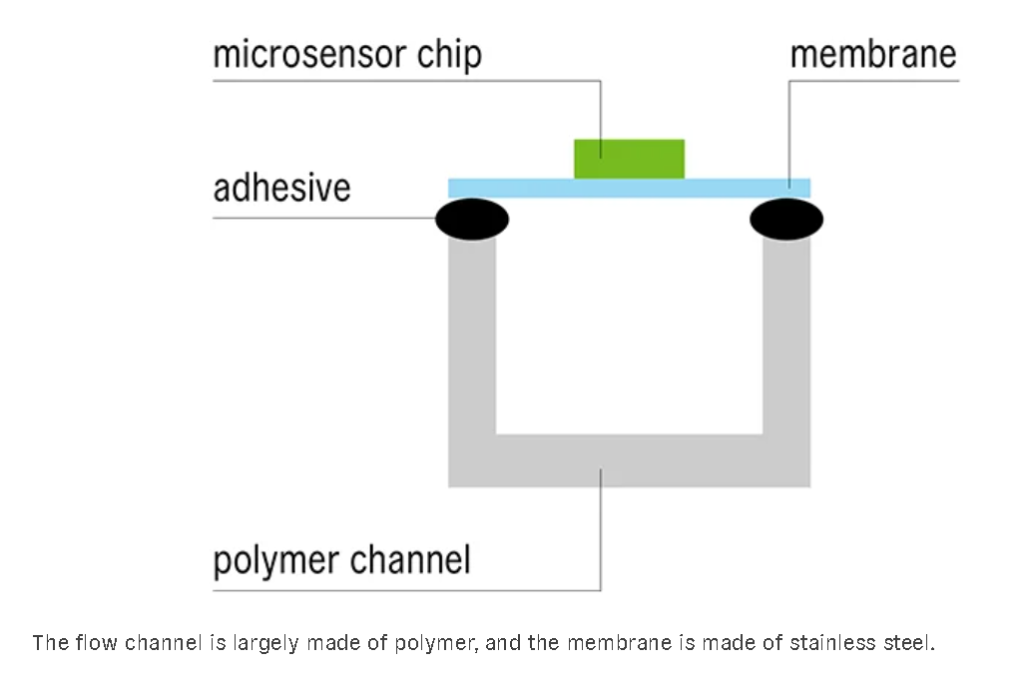

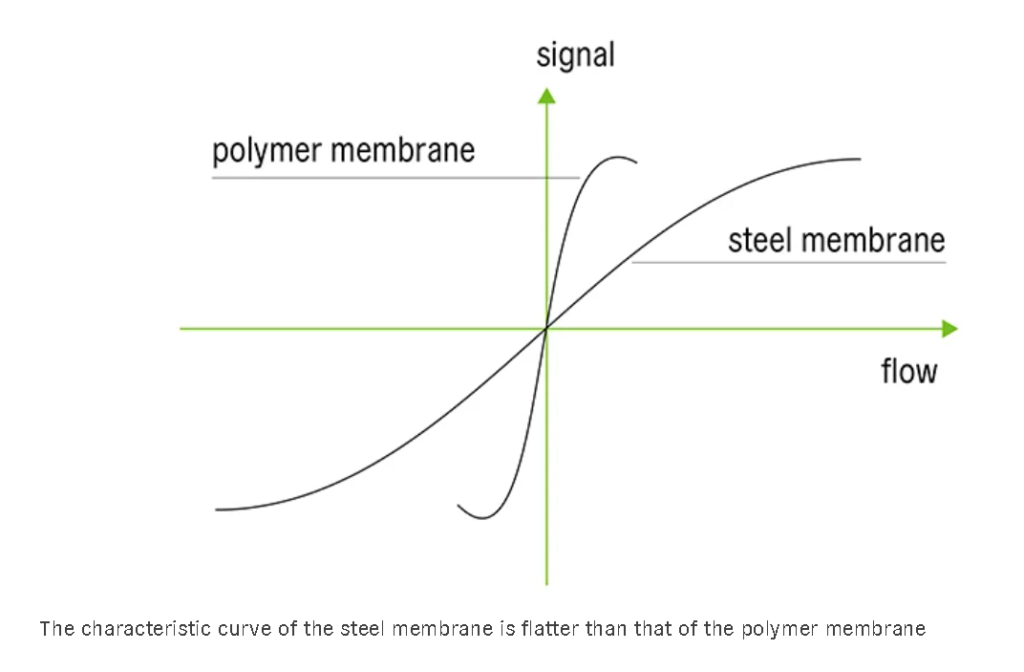

In the LD20-2600B liquid flow sensor, designed for flow rates up to 1000 ml/h, Sensirion uses a polymer membrane whose thermal conductivity, heat capacity, and heat transfer coefficient are low. However, if higher flow rates are to be measured, heat must be introduced more effectively into the flow channel. For this reason, Sensirion developers have equipped the SLF3x product family with a steel membrane. In the SLF3S-1300F, this ensures not only a larger measuring range – up to 65 ml/min – but also a wider flow rate range (see graphic), since the characteristic curve of the steel membrane is flatter than that of the polymer membrane. The newest member, the SLF3S-4000B, now opens up completely new dimensions thanks to an additional optimization of the hydrodynamic properties: this high-flow sensor is even capable of measuring flow rates of up to 1000 ml/min.

Hydrodynamic limitation overcome by W-shaped channel cross-section

The prerequisite for the thermal measuring principle is a laminar liquid flow profile. This ensures that individual fluid layers do not mix with each other in the flow, because swirling streamlines, or turbulence, disturb the temperature profile and falsify the sensor signal. An important indicator in this respect is the Reynolds number (Re), which describes the flow pattern by means of four variables: channel diameter, flow velocity, density, and the dynamic viscosity of the fluid. A lower Reynolds number (up to ca. 2300) leads to laminar flow, and a higher one (above ca. 3000) to turbulent flow. In principle, low liquid flow velocities favor laminar flow profiles, while instruments such as liquid flow controllers or sensors mounted in the channel cause turbulence.

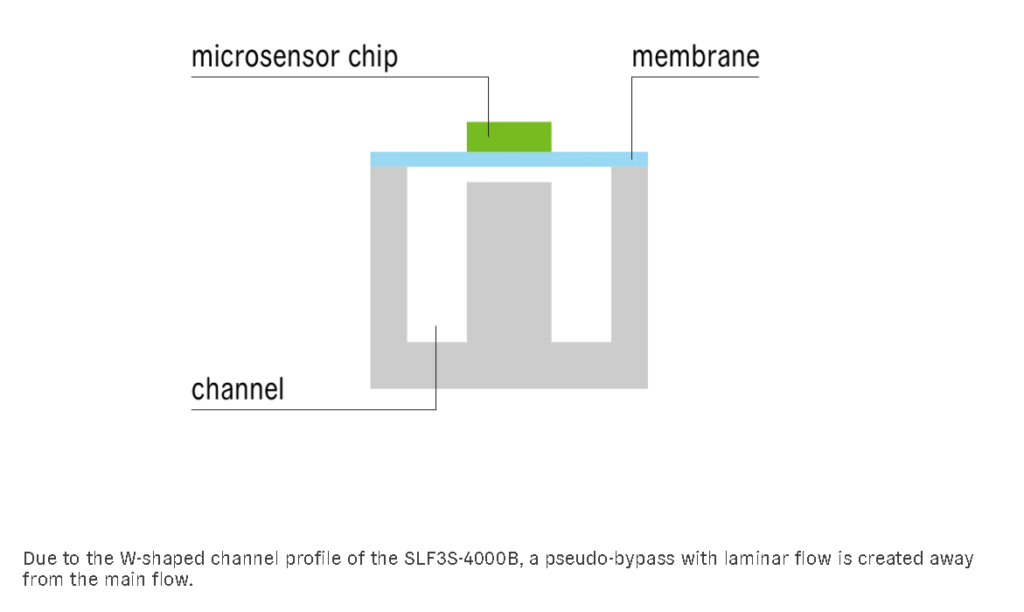

To accurately measure high flow rates, either higher flow velocities or larger channel cross-sections are required. But both factors increase the Reynolds number – and thus the likelihood of turbulence. To overcome this hydrodynamic limitation, Sensirion’s engineers employed a design trick when developing the new high-flow sensor: they laid out the new channel profile in a W-shape. This creates the possibility of positioning the MEMS chip at the narrower side stream (with laminar flow), where it can really demonstrate its measurement performance.

Physical modeling further curbs influences

During the development of the new high-flow sensor, Sensirion’s developers discovered that a number of disturbing influences have a greater impact on the measurement accuracy of sensors with a W-profile than that of conventional sensors with a round profile. For example, fluid temperature has a greater impact on the measured value because it changes not only the thermal but also the hydrodynamic properties—sometimes because the thermal conductivity of the fluid depends on the temperature. For example, increased fluid temperature reduces viscosity, which has a greater influence on the measured value in the W-profile (via the Reynolds number).

Consequently, creating an ideal measurement environment remains challenging even after overcoming thermal and hydrodynamic limitations. In order to include further influences in the calculation of flow rates, Sensirion also makes use of physical models that are incorporated in the in-house calibration and ensure that the sensor functions reliably and accurate under all conditions.

Complete portfolio: single source supply

With the new SLF3S-4000B high-flow sensor, Sensirion is moving into a new measurement dimension and now covers a considerably extended measurement range from nanoliters per minute to liters per minute. With the same look and feel as the existing three flow sensors of the SLF3x family, the SLF3S-4000B offers several advantages. Users can continue to use existing cables or software for readout without customization, thus eliminating the need to reprogram software. The complete liquid flow sensor portfolio benefits users who want to source their sensor technology exclusively from one specialist in automation solutions and fluid systems. But we are only at the beginning of the journey: Sensirion developers want to raise the bar even higher, and have their sights set on flow rates of up to 20 liters per minute. Initial field studies are already planned.

Related sensors

Active

STS40-DIS

±0.2°C Ultra-low-power temperature sensor

- Sensor

- Temperature

NRND

STS32-DIS

±0.4°C Digital temperature sensor with ISO17025 certification

- Sensor

- Temperature

NRND

STS33-DIS

±0.48°C Digital temperature sensor with ISO17025 certification

- Sens