ChatGPT said:

Getting an electronic product CE marked can be a bit of a maze if you haven’t been through it before. I’ll give you a structured breakdown of the requirements and process, specifically for electronic products (e.g., consumer devices, industrial equipment, IoT hardware).

🔑 What CE Marking Means

- CE marking is mandatory for many products sold in the EU/EEA (and recognized in the UK under UKCA with slight differences).

- It indicates that the product meets essential health, safety, EMC, and environmental protection requirements set out in European directives and regulations.

- It’s a self-declaration system, but testing and technical documentation must support it.

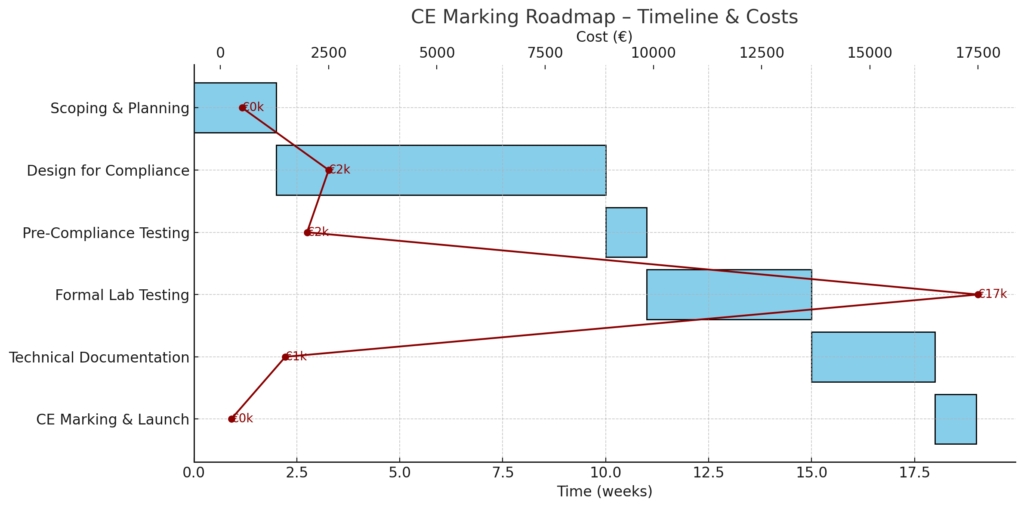

CE-marking Roadmap – TImeline & Costs

Here’s a visual roadmap showing the CE marking process:

- Blue bars = time required for each stage (in weeks).

- Red points/labels = typical cost midpoints for that stage.

📋 Step-by-Step Process for CE Marking an Electronic Product

1. Identify Applicable Directives & Regulations

Typical ones for electronics:

- Low Voltage Directive (LVD) 2014/35/EU – if operating voltage is 50–1000 VAC or 75–1500 VDC.

- EMC Directive 2014/30/EU – electromagnetic compatibility (emissions & immunity).

- Radio Equipment Directive (RED) 2014/53/EU – if product has wireless comms (Wi-Fi, Bluetooth, LTE, AIS, GPS, etc.).

- RoHS Directive 2011/65/EU (RoHS 3) – restriction of hazardous substances.

- Ecodesign / Energy Labelling – if applicable to the product type.

- Machinery Directive – if part of larger equipment.

👉 You must comply with all directives that apply to your product.

2. Identify Harmonized Standards

- Use EN harmonized standards to demonstrate compliance with directives.

Examples:- EN 55032 / EN 55035 – EMC emissions & immunity for multimedia equipment.

- EN 301 489 – EMC for radio devices.

- EN 62368-1 – Electrical safety (ICT & AV equipment).

- EN 300 328 – 2.4 GHz ISM band radio (Wi-Fi/Bluetooth).

- EN 50581 – RoHS documentation.

👉 Testing against harmonized standards gives a “presumption of conformity”.

3. Carry Out Risk Assessment

- Perform a risk analysis for safety hazards: electrical shock, overheating, fire, mechanical, chemical.

- Document mitigations (fuses, insulation, shielding, thermal cutoffs, safe firmware states).

4. Product Testing

- EMC Testing – emissions + immunity in an accredited lab.

- Safety Testing – insulation, creepage/clearance, fire hazards.

- Radio Testing (if applicable) – spectrum efficiency, coexistence, spurious emissions.

- Environmental / RoHS – materials analysis (usually through supplier declarations).

Testing can be in-house (if you have a compliant setup) but is usually done in an accredited test house for credibility.

5. Compile the Technical Documentation (“Technical File”)

Must be kept for 10 years after last product sold.

Includes:

- Product description, model numbers, photos.

- Design drawings, schematics, PCB layouts.

- BOM with material declarations (RoHS).

- Test reports (EMC, safety, radio).

- Risk assessment.

- User manual & safety instructions.

- Declaration of Conformity (DoC).

6. Draft the EU Declaration of Conformity (DoC)

- Formal legal document signed by the manufacturer (or authorized EU representative).

- States compliance with all applicable directives and standards.

- Must include: product details, directives, standards used, manufacturer name & address, signatory, date.

7. Affix the CE Marking

- Must be visible, legible, and indelible on the product, packaging, and instructions.

- If a Notified Body was involved (required for certain products under RED), their 4-digit ID number goes next to the CE mark.

⚡ Common Pitfalls

- Skipping EMC pre-compliance → failures late in the process.

- Assuming only EMC applies (forgetting safety or RED).

- Weak documentation – EU market surveillance authorities can request the technical file at any time.

- Incorrect CE mark sizing (minimum 5 mm height).

✅ Summary Checklist

- Identify directives (LVD, EMC, RED, RoHS, etc.).

- Apply harmonized EN standards.

- Perform risk assessment.

- Test (EMC, safety, radio, materials).

- Compile technical file.

- Draft & sign DoC.

- Affix CE marking.

Do you want me to also make a practical roadmap with timeline and cost ranges (lab testing fees, documentation effort, etc.), so you can see what’s involved if you’re putting a new electronic product through CE approvals?

You said:

yes, also make a practical roadmap with timeline and cost ranges

ChatGPT said:

Great — let’s make this practical. I’ll give you a realistic roadmap, broken down by stages, with timeframes and cost ranges based on typical experiences of small to medium electronics manufacturers.

📅 Roadmap for CE Marking an Electronic Product

Stage 1 – Scoping & Planning

Activities

- Identify which EU Directives apply (EMC, LVD, RED, RoHS, etc.).

- Choose relevant harmonized standards.

- Create early compliance plan.

- Engage a test house (get quotes).

Timeframe: 1–2 weeks

Costs: €0–€1,000 (mostly internal effort; maybe consultant fees)

Stage 2 – Design for Compliance

Activities

- PCB design with EMC/safety practices (grounding, shielding, creepage/clearance, filters).

- Choose compliant components (RoHS declarations from suppliers).

- Draft user manual (safety notes required for LVD/RED).

- Pre-compliance checks (in-house or at test lab).

Timeframe: Parallel with product design (4–12 weeks)

Costs: €0–€5,000 (extra design effort, pre-compliance scans, consultant input)

Stage 3 – Pre-Compliance Testing (Optional but Recommended)

Activities

- Do early EMC testing in a pre-compliance chamber to catch major failures before final certification.

- Conduct basic safety checks (creepage, leakage current, insulation tests).

Timeframe: 1 week

Costs: €1,000–€3,000 (half-day to full-day chamber rental)

Stage 4 – Formal Laboratory Testing

Activities

Depends on product type:

- EMC (EMC Directive 2014/30/EU)

- Radiated/conducted emissions, ESD, EFT, surge, RF immunity.

- Safety (LVD / EN 62368-1, etc.)

- Dielectric withstand, leakage, abnormal operation, thermal hazards.

- Radio (RED Directive 2014/53/EU) (if wireless)

- RF power, occupied bandwidth, spurious emissions, coexistence.

- RoHS

- Typically supplier declarations; some labs offer material screening.

Timeframe: 2–6 weeks (including booking + retests if failures)

Costs (typical EU test house fees):

- EMC only: €5,000–€10,000

- Safety only: €3,000–€8,000

- Radio testing: €8,000–€15,000 (per band/technology)

- RoHS screening: €1,000–€2,000 (if not just supplier docs)

👉 Total typical: €10,000–€25,000 per product variant

Stage 5 – Technical Documentation

Activities

- Compile Technical File: schematics, PCB layouts, test reports, risk assessment, manuals, BOM + RoHS evidence.

- Draft the Declaration of Conformity (DoC).

Timeframe: 2–4 weeks

Costs: €0–€3,000 (in-house vs. consultant preparation)

Stage 6 – CE Marking & Product Launch

Activities

- Affix CE marking to product, packaging, and user manual.

- Keep Technical File available for 10 years.

- If requested, provide docs to EU Market Surveillance Authority within 10 days.

Timeframe: Immediate after approval

Costs: Negligible (printing, labeling)

🕒 Total Timeline

- Simple non-radio product (EMC + LVD + RoHS) → ~3–6 months

- Radio-enabled product (RED + EMC + LVD + RoHS) → ~6–12 months

💶 Total Cost Ranges

- Non-radio electronics (wired device, low complexity): €8,000–€15,000

- Wireless / IoT product (Wi-Fi/Bluetooth, GPS, AIS, LTE, etc.): €15,000–€40,000

- Complex multi-radio system (e.g. cellular + Wi-Fi + Bluetooth): €30,000–€70,000

⚡ Practical Tips

- Budget for retests: Most products fail at least one EMC or radio test the first time.

- Use pre-certified radio modules (e.g. ESP32, Quectel LTE modules) → reduces RED testing costs significantly.

- Work with the test house early: they can advise on design tweaks before formal testing.

- Plan variants carefully: each major variant (frequency band, enclosure change, power supply change) may need separate testing.

👉 Do you want me to make you a visual roadmap (timeline with milestones, cost bars) so you can use it as a planning/management tool for an upcoming product?